cut to size,fabricate or machine plastics to your specifications

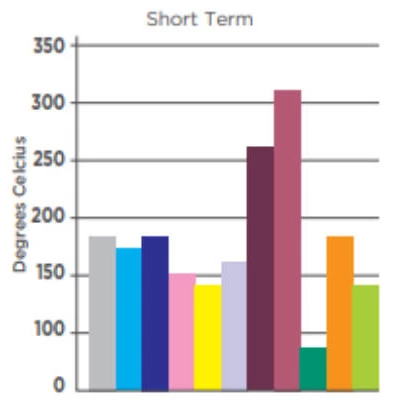

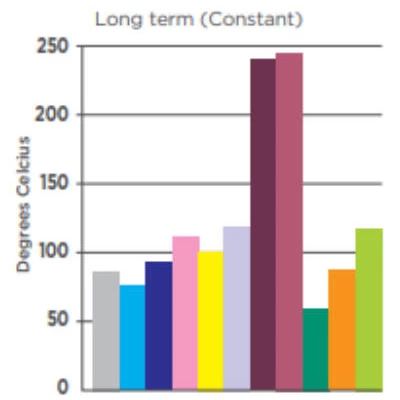

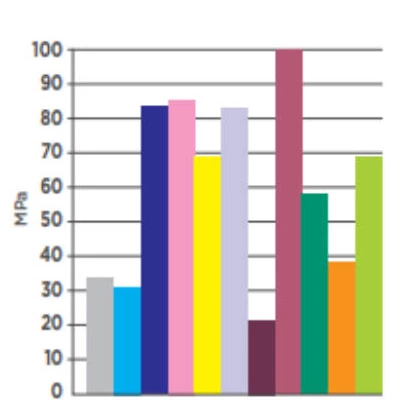

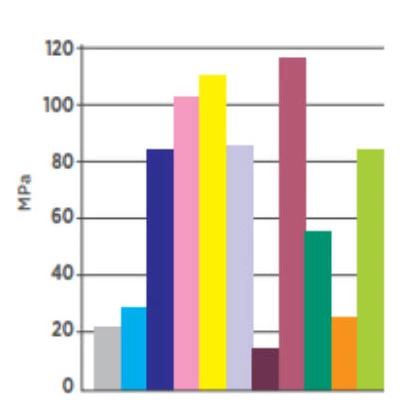

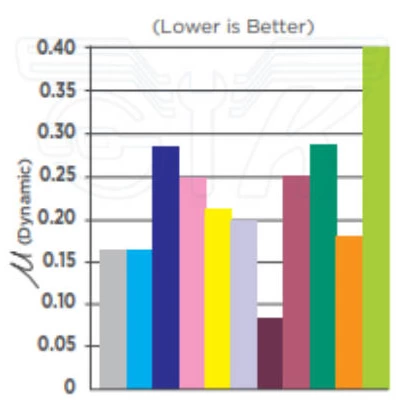

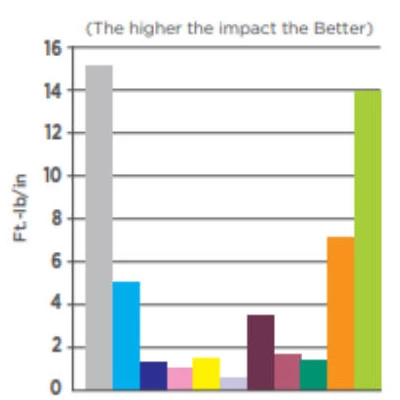

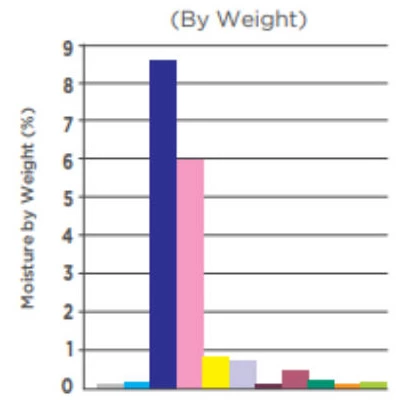

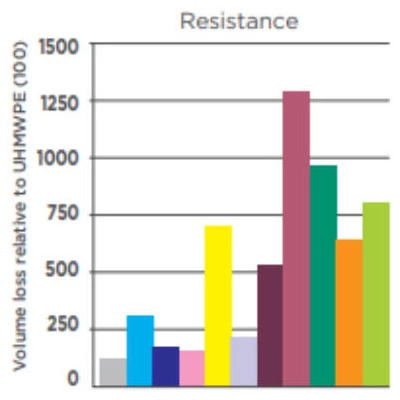

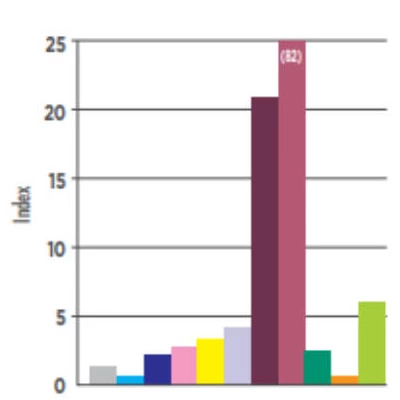

PE-UHMW

PE-HD

Ext. Nlylon

Cast Nylon

Acetal PoM-C

Polyester PET-P

PTFE

PEEK

PVC

Polypropylene PP

Polycarbonate PC

Discover how our high-performance engineering plastic components perform in real working environments. From wear-resistant UHMWPE liners to precision-machined POM, Nylon, and PTFE parts, our application videos demonstrate durability, stability, and long-term performance across mining, marine, conveying, and heavy-equipment operations.

Used in many industrial and consumer applications

Excellent tribological properties

Fantastic chemical resistance

Suitable for food contact

Excellent dielectric properties

Not glueable

Average mechanical properties

Process: CNC Machining

Tolerance: ISO 2768-1 medium (m) class

Max size: 500x500x90mm; 19.7x19.7x3.54in

Lead time: <2 days

Durable and cost-effective

Self-extinguishing UL94 V0

Rigid and with good mechanical properties

Easy to machine and weld

Excellent electrical insulation

Limited ductility and resilience

Not suitable for food contact

The maximum operating temperature is 60°C

Machining process: CNC

Tolerance: ISO 2768-1 medium (m) class

Max size: 500x500x50mm; 20x20x2in

Lead time: <3 days

PEEK features and CNC properties, for demanding applications

Dimensional accuracy

High temperature resistance

Very high specific strength

Flame retardant UL94 V0

Food contact certified

Tool marks could be visible

Limited geometric freedom

High cost

Machining process: CNC

Tolerance: ISO 2768-1 fine (f) or medium (m) class

Max size: 500x450x55mm 19,6x17,7x2,2in

Lead time: <3 days

Mechanical properties and chemical resistance

Good mechanical properties in wide-ranging temperatures

Suitable for contact with food

Oil and fats good inertia

Minimum tolerance of ±0.10 mm

Process: CNC Machining

Tolerance: ISO 2768-1 medium (m) class

Max size: 500x500x140mm ; 19.7x19.7x5.5 in

Lead time: <4 days

Good workability, excellent for high-performance parts

Good mechanical properties in wide-ranging temperatures

Suitable for direct contact with food

Oil and fats good inertia

Minimum tolerance of ±0.10 mm

Machining Process: CNC

Tolerance: ISO 2768-1 medium (m) class

Max size: 500x500x95mm; 19.7x19.7x3.7in

Lead time: <3 days

Chemical resistance, electrical insulation and tensile strength

Lightweight

Excellent chemical resistance

Tensile strength

Electrical insulation

Limited thermal resistance

Susceptibility to UV degradation

Machining process: CNC

Tolerance: ISO 2768-1 medium (m) class

Max size: 500x500x90 mm; 119.7x19.7x3.54 in

Lead time: <4 days

Offers excellent impact resistance, good rigidity and durability

Good tribological properties

Good impact resistance

Good scratch resistance

Low UV resistance

Poor chemical resistance

Process: CNC Machining

Tolerance: ISO 2768-1 medium (m) class

Max size: 500x500x50mm; 119.7x19.7x2in

Lead time: <2 days

Reach out to our team to request UHMWPE material or finished component samples and experience our manufacturing quality firsthand. We’re ready to support your projects with reliable, high-performance polyethylene solutions.

We are a professional HDPE sheet manufacturing factory, specializing in producing high-quality, custom-engineered HDPE sheets through advanced extrusion technology. Our commitment is to provide durable, versatile, and sustainable solutions for a wide range of industrial and commercial needs. Through continuous innovation and stringent quality control in our extrusion process, we ensure our products meet the highest standards of performance and reliability.

Welcome to our dedicated Engineering Plastic Machining Workshop, where precision meets performance. We specialize in transforming high-quality engineering plastics into custom, high-tolerance components through advanced CNC and fabrication processes.

We specialize in high-precision CNC machining of a wide range of engineering plastics. Utilizing advanced CNC machinery, we transform plastic sheets, rods, and profiles into custom components with tight tolerances and complex geometries. With deep expertise in material properties (such as POM/Nylon/PTFE/PP/PE/PEEK), we provide end-to-end solutions from rapid prototyping to low-volume production. Our parts are engineered to meet specific requirements for strength, wear resistance, chemical resistance, or insulation. Whether for mechanical components, jigs & fixtures, valve seats, or specialized structures, we are committed to delivering craftsmanship and reliability as your trusted partner for precision plastic parts.

For more information about UHMWPE materials and custom-machined components, please contact us.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details